An Intensive 3-Day Training Course

Introduction to Total Productive Maintenance (TPM): Planning & Implementation

Introduction to Total Productive Maintenance (TPM): Planning & Implementation

Tutor-Led Class @ NGN150,000.00 per Participant

Online @ NGN120,000.00 Per participant

On-Site to make formal request

Venue: Mechelectric Conference Centres, Ikeja, Abuja, PH and Ota

Date and Time: October 8 - 11, 2025; 0900Hr - 1600Hr Daily

Course Overview

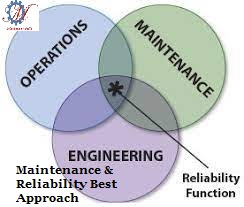

Total Productive Maintenance is the cornerstone of any production process. Get it right and you can enjoy good safety performance, low running costs and a sustainably high production level at the right quality. Productive plants are usually safer and cite a higher level of morale. Weak control of Total Productive Maintenance results in operations becoming weak and less predictable, more chaotic and much more difficult to control. This WorkmanSkills training is a highly practical course that includes the latest thinking in Total Productive Maintenance improvement, how to gain maximum benefit for minimum effort and how to develop bespoke productive strategies that will integrate effectively with other campaigns.

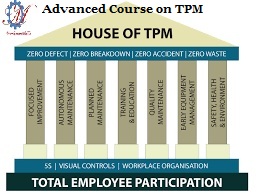

As a company-wide initiative, Total Productive Maintenance (TPM) maximizes the effectiveness and longevity of equipment. The TPM program significantly increases labor and capital productivity while, at the same time, increases employee morale and job satisfaction. TPM brings maintenance into focus as a necessary and vitally important part of the business. Targeted at all levels of the organization, TPM and its 8 Pillars provide the necessary supporting process and tools to achieve zero defects, zero breakdowns and zero accidents.

This comprehensive WorkmanSkills training course combines the TPM tools, 5S, OEE (Overall Equipment Effectiveness), 8 pillars (including Autonomous and Planned maintenance) into a highly detailed training tool. It includes a step-by-step implementation process of TPM.

Course Benefits:

By attending this WorkmanSkills training, delegates will be able to:

This WorkmanSkills training course is ideal for wide range of engineering/maintenance professionals but will greatly benefit:

How will this Training Course be Presented?

This WorkmanSkills training course will utilize a variety of proven learning techniques to ensure maximum understanding, comprehension, and retention of the information presented.

Course Outlines

The Certificate

Certificate of Completion will be provided to delegates who attend and complete the course

Total Productive Maintenance is the cornerstone of any production process. Get it right and you can enjoy good safety performance, low running costs and a sustainably high production level at the right quality. Productive plants are usually safer and cite a higher level of morale. Weak control of Total Productive Maintenance results in operations becoming weak and less predictable, more chaotic and much more difficult to control. This WorkmanSkills training is a highly practical course that includes the latest thinking in Total Productive Maintenance improvement, how to gain maximum benefit for minimum effort and how to develop bespoke productive strategies that will integrate effectively with other campaigns.

As a company-wide initiative, Total Productive Maintenance (TPM) maximizes the effectiveness and longevity of equipment. The TPM program significantly increases labor and capital productivity while, at the same time, increases employee morale and job satisfaction. TPM brings maintenance into focus as a necessary and vitally important part of the business. Targeted at all levels of the organization, TPM and its 8 Pillars provide the necessary supporting process and tools to achieve zero defects, zero breakdowns and zero accidents.

This comprehensive WorkmanSkills training course combines the TPM tools, 5S, OEE (Overall Equipment Effectiveness), 8 pillars (including Autonomous and Planned maintenance) into a highly detailed training tool. It includes a step-by-step implementation process of TPM.

Course Benefits:

By attending this WorkmanSkills training, delegates will be able to:

- Explain how pace-setters achieve outstanding TPM performance and how to use the Carcharodon Model of Excellence

- Develop TPM programs that align with the unique needs of their business, asset and maintenance strategies

- Analyze their current performance against best-in-class benchmarks

- Calculate potential fixed and variable cost reductions along with productivity, output, and product quality improvements, that can be delivered through TPM improvement

- Apply key TPM improvement methodologies and tools to improve performance

- Explain to colleagues the fundamentals of best practice in TPM, including the responsibilities of design and operations as well as maintenance

- Engage colleagues and consider the human factors required to support a high TPM culture

- Understand the concept and management philosophy of TPM as a foundation for Lean Transformation

- Learn the 8 pillars of TPM activities, TPM implementation strategy, roadmap and step-by-step approach

- Learn the TPM tools and be able to identify and eliminate loss through TPM implementation

- Learn how to kick-start TPM deployment with the key pillars such as Autonomous Maintenance, Planned Maintenance, Focused Improvement and Education & Training activities to improve equipment reliability

- Understand the roles of a TPM implementation organization and the critical success factors

This WorkmanSkills training course is ideal for wide range of engineering/maintenance professionals but will greatly benefit:

- Maintenance Managers

- Maintenance Supervisors & Technicians

- Operators

- Production Managers & Supervisors

- Quality Control/Quality Assurance Personnel

- Operations Managers & Supervisors

- Stores Personnel

- Finance & Accounting Personnel

- This course is also designed for persons who want to contribute to the TPM performance in the workplace.

How will this Training Course be Presented?

This WorkmanSkills training course will utilize a variety of proven learning techniques to ensure maximum understanding, comprehension, and retention of the information presented.

Course Outlines

- An introduction to TPM

- Calculating the value of cost reduction and increased production

- The impact of reliability on safety, quality and team morale

- Overall Equipment Effectiveness (OEE), an international model for measuring asset performance

- A definition of maintenance

- The move to asset management and the modern maintenance strategy

- Sources of losses and the role of operations, design and procurement

- Contractors, materials and equipment

- The TPM pyramid

- TPM benchmarks

- The link between performance and TPM practices

- Where to look for best practice

- Case studies of pace setter methodologies

- A Model of Excellence for TPM

- Building a reliability focused supply chain

- Customer focused TPM

- Base-lining plant performance

- How to project the potential level of improvement

- Calculating the benefits case

- How to focus on the most valuable priorities for any business

- Using the Define, Measure, Analyze, Improve and Control (DMAIC) methodology for structured performance improvement

- An end to end process for TPM improvement and asset life extension

- Key principles of reliability centered maintenance, Total Productive Maintenance (TPM) and Six Sigma

- Using Root Cause Analysis to address historic failures

- Criticality analysis to prioritize reliability efforts

- Proactively avoiding future failures using Failure Mode Effect Analysis

- Reliability by design

- The 5S process for improving ergonomics and identifying issues

- An introduction to the Single-Minute Exchange of Die (SMED) process for reducing downtime to repair

- When to consider advanced software models

- TPM focused shutdowns and turnarounds

- The impact of human factors on TPM performance

- Gaining buy in beyond just the maintenance team

- How to get people to own TPM

- Developing a TPM culture

- The importance of data in performance improvement

- TPM metrics

- Use of Pareto analysis

- Loss accounting and failure reporting

- TPM roles and organizing for success

The Certificate

Certificate of Completion will be provided to delegates who attend and complete the course