An Intensive 3-Day Training Course

Advanced Course on Reliability Centered Maintenance: Policy & Implementation Best Practices

Advanced Course on Reliability Centered Maintenance: Policy & Implementation Best Practices

Tutor-Led Class @ NGN200,000.00 per Participant

Online @ NGN180,000.00 Per participant

On-Site to make formal request

Venue: Mechelectric Conference Centres, Ikeja, Abuja, PH and Ota

Date and Time: January 14 - 16, 2025; 0900Hr - 1600Hr Daily

Course Overview

The maintenance of physical assets can no longer be treated just as a ‘maintenance problem’. The competitive environment in which business operates requires an approach that integrates the operational objectives of the business and the life-cycle objectives of the physical assets.

Our highly interactive Maintenance Planning, Scheduling & Work Control training course is designed to provide management and staff with essential maintenance management skills, gain a clear understanding of their roles, and work more effectively within a team environment.

Delegates will gain a practical understanding and knowledge of:

This WorkmanSkills training course is designed to provide delegates with essential maintenance management skills, gain a clear understanding of their roles, and work more effectively within a team environment.

Course Benefits

By attending this WorkmanSkills training, delegates will be able to:

Target Audience:

Delegates should represent a wide range of personnel in the organization who are involved in, or dependent on, effective maintenance planning, scheduling and work control. These should include:

How will this Training Course be Presented?

Facilitated by an experienced maintenance specialist, this WorkmanSkills Maintenance Planning, Scheduling & Work Control training course will be conducted as a highly interactive work session (as opposed to lectures), encouraging participants to share their own experiences and apply the training course material to real-life situations. Training course size will be limited to 30 delegates in order to stimulate discussion and efficiency of subject coverage.

Each delegate will receive an extensive reference manual, as well as case studies, while worked out solutions will be handed out to the delegates on conclusion of group discussions. Throughout the training course, delegates will be encouraged to identify what they can do to enhance Maintenance Planning, Scheduling & Work Control in their organizations.

Course Outlines

Module 1 : Modern Maintenance Management Practice in Perspective

WorkmanSkills Certificate of Completion will be provided to delegates who attend and complete the course

The maintenance of physical assets can no longer be treated just as a ‘maintenance problem’. The competitive environment in which business operates requires an approach that integrates the operational objectives of the business and the life-cycle objectives of the physical assets.

Our highly interactive Maintenance Planning, Scheduling & Work Control training course is designed to provide management and staff with essential maintenance management skills, gain a clear understanding of their roles, and work more effectively within a team environment.

Delegates will gain a practical understanding and knowledge of:

- The essential principles of effective maintenance management

- Effective procedures for planning and controlling of the maintenance work flow

- Proven methodology for the development of an effective maintenance plan

- Effective scheduling of maintenance work

- Closing the management loop through effective measurement, reporting and analysis

This WorkmanSkills training course is designed to provide delegates with essential maintenance management skills, gain a clear understanding of their roles, and work more effectively within a team environment.

Course Benefits

By attending this WorkmanSkills training, delegates will be able to:

- Understand maintenance as a key business function

- Understand the objectives and purpose of pro-active failure management

- Learn how reliability influences not only plant output, but also improves health, safety and environmental performance, resource optimization and cost improvement

- Identify planning and scheduling best practices and how these will contribute to work quality and reliability improvement

- Create and preserve forward work and use it for planning and scheduling resources

- Use suitable performance indicators and management reports to perform regular analysis of maintenance performance, control maintenance resources and costs, and drive continuous improvement

Target Audience:

Delegates should represent a wide range of personnel in the organization who are involved in, or dependent on, effective maintenance planning, scheduling and work control. These should include:

- Maintenance and Operations Professionals

- Maintenance Engineers and Supervisors

- Maintenance Planners, Schedulers and Work Preparers

- Key Operations Supervisors

- CMMS Administrator or Key Users

- Key Maintenance Support Assistants

- Other stakeholders in the Maintenance Function

How will this Training Course be Presented?

Facilitated by an experienced maintenance specialist, this WorkmanSkills Maintenance Planning, Scheduling & Work Control training course will be conducted as a highly interactive work session (as opposed to lectures), encouraging participants to share their own experiences and apply the training course material to real-life situations. Training course size will be limited to 30 delegates in order to stimulate discussion and efficiency of subject coverage.

Each delegate will receive an extensive reference manual, as well as case studies, while worked out solutions will be handed out to the delegates on conclusion of group discussions. Throughout the training course, delegates will be encouraged to identify what they can do to enhance Maintenance Planning, Scheduling & Work Control in their organizations.

Course Outlines

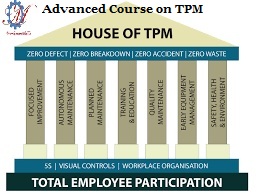

Module 1 : Modern Maintenance Management Practice in Perspective

- Maintenance in the Business Process

- What does it looks like

- What it could look like

- Evolution in Maintenance Management

- Reactive vs. Proactive Maintenance

- World-Class Maintenance Management

- Equipment Classification and Identification

- Document Identification and Classification

- Maintenance Management Policies

- Maintenance Work Prioritization

- Maintenance Logistics Planning

- Failure Modes, Effects and Consequences (FMEA)

- Failure Management Policies

- Application of RCM in the Development of Failure Management Policies

- Implementing Failure Management Policies

- Corrective Maintenance Planning

- Logistic Requirements Planning

- Development of Weekly Master Schedule

- Determine Resource Availability

- Determine Equipment Outage Requirement

- Management of the Forward Workload (Backlog)

- Weekly Master Schedule Implementation

- Information and Control

- Management Levels and Information

- Performance Indicators

- Workload Performance Indicators

- Planning Performance Indicators

- Effectiveness Performance Indicators

- Cost Performance Indicators

- Management Reports

- Case Studies and Group Discussions

WorkmanSkills Certificate of Completion will be provided to delegates who attend and complete the course