An Intensive 2-Day Training Course

Optimizing Productivity Through the Identification & Implementation of Appropriate Maintenance Strategy

Optimizing Productivity Through the Identification & Implementation of Appropriate Maintenance Strategy

Tutor-Led Class @ NGN120,000.00 per Participant

Online @ NGN100,000.00 Per participant

On-Site to make formal request

Venue: Mechelectric Conference Centres, Ikeja, Abuja, PH and Ota

Date and Time: April 1 - 2, 2025; 0900Hr - 1600Hr Daily

Course Overview

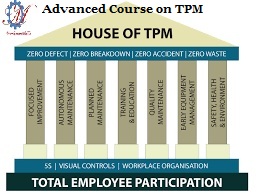

How do organizations improve productivity? What is productivity to start with? This WorkmanSkills course presents maintenance best practices on how to boost productivity by focusing on quality and cost saving initiatives. In this course we will share best practices and tools from organizations that implemented effective maintenance methodologies to improve their processes and achieve faster cycle times, lesser defects and simplified operations. Participants will also learn how to apply these practices in their organizations and understand how to manage change. They will master the skills to leverage the existing culture to their advantage by creating a solid platform and moving the organization into a new mindset. This course is critical for every organization aiming to save cost and become more efficient and productive.

Course Benefits

By attending this WorkmanSkills training, delegates will be able to:

Target Audience:

This WorkmanSkills training is ideal for wide range of engineering/maintenance professionals but will greatly benefit:

How will this Training Course be Presented?

This WorkmanSkills training course will utilize a variety of proven learning techniques to ensure maximum understanding, comprehension, and retention of the information presented.

Course Outlines

WorkmanSkills Certificate of Completion will be provided to delegates who attend and complete the course

How do organizations improve productivity? What is productivity to start with? This WorkmanSkills course presents maintenance best practices on how to boost productivity by focusing on quality and cost saving initiatives. In this course we will share best practices and tools from organizations that implemented effective maintenance methodologies to improve their processes and achieve faster cycle times, lesser defects and simplified operations. Participants will also learn how to apply these practices in their organizations and understand how to manage change. They will master the skills to leverage the existing culture to their advantage by creating a solid platform and moving the organization into a new mindset. This course is critical for every organization aiming to save cost and become more efficient and productive.

Course Benefits

By attending this WorkmanSkills training, delegates will be able to:

- Define productivity and various types of organizational waste

- Identify areas of poor productivity due to poor quality and suggest ways to increase effectiveness and efficiency

- Justify and apply quality improvement tools and techniques in order to improve productivity

- Apply several cost reduction strategies in order to meet changing global, statutory and market conditions

- Recognize and apply measuring initiatives and set targets in order to improve productivity

Target Audience:

This WorkmanSkills training is ideal for wide range of engineering/maintenance professionals but will greatly benefit:

- Engineers

- Laboratory Technicians

- Supervisors

- Planners

- Production Personnel

- Managers

- Operators

- Technicians

How will this Training Course be Presented?

This WorkmanSkills training course will utilize a variety of proven learning techniques to ensure maximum understanding, comprehension, and retention of the information presented.

Course Outlines

- Definitions

- Productivity limitations

- Process based view

- The 'Muda' factor

- Eight types of waste

- Cost of poor quality

- Quality defined

- Cornerstones of quality

- Barriers to cost reduction programs

- Setting up a cost reduction program

- Resistance psychology in humans

- Techniques to involve employees in your quality improvement tasks

- The role of suggestion schemes

- Productivity improvement project road map

- World-Class Maintenance-Mix

- The 'Focus' method

- SMART practices for increasing productivity

- Cost savings opportunities

- Barriers to a cost cutting program

- Getting commitment to a cost cutting program

- One hundred and forty ideas to cut costs

- Key performance indicators

- Types of measures

- Setting targets for cost reduction

- Bench-marking

- Types of bench-marking

WorkmanSkills Certificate of Completion will be provided to delegates who attend and complete the course