An Intensive 5-Day Training Course

Material Selection, Machinery Failure Analysis & Troubleshooting

Material Selection, Machinery Failure Analysis & Troubleshooting

Tutor-Led Class @ NGN250,000.00 per Participant

Online @ NGN230,000.00 Per participant

On-Site to make formal request

Venue: Mechelectric Conference Centres, Ikeja, Abuja, PH and Ota

Date and Time: September 1 - 5, 2025; 0900Hr - 1600Hr Daily

Course Overview

Mechanical equipment and systems in handle a variety of hazardous or even lethal substances that may also be corrosive. Many operate at high temperatures and pressures and are subjected to service conditions that could cause degradation and damage to the equipment, and if such damage is not detected and assessed in a timely manner, it could result in catastrophic failures with potentially enormous consequential losses of life and assets.

The potential degradation mechanisms, such as fracture, corrosion, erosion, fatigue, creep etc., that the equipment is likely to be subjected to in service must be taken into consideration in the design of the equipment. This is typically accounted for in the design through the selection of appropriate materials of construction, providing corrosion allowances in the form of additional thickness, providing control measures and incorporating safeguards and engineering controls to prevent operation outside the design envelope, and maintain the integrity of the equipment. In certain instances, total replacement of the equipment or system/circuit may be required.

Consequently, it is essential to inspect the mechanical equipment and systems with the view to detect any damage, characterize it, and assess its impact on the equipment integrity, in addition to Fitness-for-Service assessments.

A key objective of this comprehensive course is to provide the participants with a clear understanding of Materials Selection and the degradation mechanisms that mechanical equipment could be subjected to over their operating life, how to identify them, predict and determine their impact, and what appropriate measures can be taken to prevent and control the resultant damage.

This WorkmanSkills training course will include possible actions necessary for retaining a system, or restoring to it, a serviceable condition, include servicing, repair, modification, overhaul, inspection and condition verification. This increases the availability of the system and help to keep system’s equipment in working order.

This training course will feature:

Course Benefits:

At the end of the programme, participants will be able to:

Course Outlines:Day One: Mechanical Testing and Damage Mechanisms

Target Audience:

How will this Training Course be Presented?

This WorkmanSkills training course will utilize a variety of proven online learning techniques to ensure maximum understanding, comprehension, and retention of the information presented.

The Certificate

WorkmanSkills Certificate of Completion will be provided to delegates who attend and complete the course

Mechanical equipment and systems in handle a variety of hazardous or even lethal substances that may also be corrosive. Many operate at high temperatures and pressures and are subjected to service conditions that could cause degradation and damage to the equipment, and if such damage is not detected and assessed in a timely manner, it could result in catastrophic failures with potentially enormous consequential losses of life and assets.

The potential degradation mechanisms, such as fracture, corrosion, erosion, fatigue, creep etc., that the equipment is likely to be subjected to in service must be taken into consideration in the design of the equipment. This is typically accounted for in the design through the selection of appropriate materials of construction, providing corrosion allowances in the form of additional thickness, providing control measures and incorporating safeguards and engineering controls to prevent operation outside the design envelope, and maintain the integrity of the equipment. In certain instances, total replacement of the equipment or system/circuit may be required.

Consequently, it is essential to inspect the mechanical equipment and systems with the view to detect any damage, characterize it, and assess its impact on the equipment integrity, in addition to Fitness-for-Service assessments.

A key objective of this comprehensive course is to provide the participants with a clear understanding of Materials Selection and the degradation mechanisms that mechanical equipment could be subjected to over their operating life, how to identify them, predict and determine their impact, and what appropriate measures can be taken to prevent and control the resultant damage.

This WorkmanSkills training course will include possible actions necessary for retaining a system, or restoring to it, a serviceable condition, include servicing, repair, modification, overhaul, inspection and condition verification. This increases the availability of the system and help to keep system’s equipment in working order.

This training course will feature:

- Study of mechanical faults related to mechanical equipment

- Failure modes including fracture, fatigue, high temperature creep and corrosion damage

- Materials types and selection

- Condition monitoring and trending

- Knowledge of non-destructive testing

- Fault Fining and Maintenance Techniques

Course Benefits:

At the end of the programme, participants will be able to:

- Provide participants with the main failure mechanisms of equipment

- Introduce materials types and selection

- Attempt to maximize and customer satisfaction and performance of production equipment efficiently and, regularly, through high utilization of facility and adjusted and serviced equipment.

- Prevent breakdown or failures and minimize frequency and severity of interruptions

- Maximize useful life of equipment and minimize production loss from failures

- Increase reliability of the operating systems

- Keep equipment safe and prevent safety hazards

Course Outlines:Day One: Mechanical Testing and Damage Mechanisms

- Tensile, stress, strain, ductility

- Brittle, Ductile Fracture

- Impact, Toughness

- Low temperature consideration

- Design Examples

- Crystalline structure of metals

- Types of steel

- Stainless steels

- Cast Irons

- Nickel based alloys

- Selection of metals for different applications

- Fracture Mechanics

- Fatigue failure

- Creep, high temperature failure

- Corrosion types

- Corrosion control

- Condition monitoring

- Vibration measurements and analysis

- Fault types and recognition

- Condition Trending

- Boroscope

- Dye penetrant

- Magnetic methods

- X-ray methods

- Gama - ray methods

- Ultra-sonic methods

- Eddy current testing

- Root Cause Analysis

- HAZOP Analysis

- Fault tree analysis

- Fishbone Diagram

- Pareto Analysis

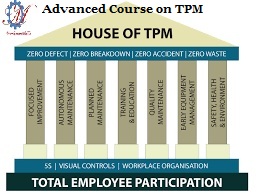

- Types of maintenance

- Inspection codes

Target Audience:

- General Engineers

- Plant Engineers

- Maintenance Personnel and Supervisors

- Technicians

- Other technical individuals

How will this Training Course be Presented?

This WorkmanSkills training course will utilize a variety of proven online learning techniques to ensure maximum understanding, comprehension, and retention of the information presented.

The Certificate

WorkmanSkills Certificate of Completion will be provided to delegates who attend and complete the course