An Intensive 5-Day Training Course

Maintenance & Reliability Best Practice in the Manufacturing Environment

Maintenance & Reliability Best Practice in the Manufacturing Environment

Tutor-Led Class @ NGN250,000.00 per Participant

Online @ NGN230,000.00 Per participant

On-Site to make formal request

Venue: Mechelectric Conference Centres, Ikeja, Abuja, PH and Ota

Date and Time: November 3 - 7, 2025; 0900Hr - 1600Hr Daily

Course Overview

Lower revenues due to lower commodity prices have placed equipment life-cycle costs under the management spotlight like never before. Maintainers are faced with the challenge to deliver the same levels of equipment safety, reliability and availability with smaller budgets. This WorkmanSkills Maintenance & Reliability training course introduces the practical tools and practices that organisations need to adopt to drive down their equipment life-cycle costs in practical ways.

This WorkmanSkills training course emphasizes the most effective strategies, policies, tactics and practices that are needed to ensure the reliability, integrity and durability of the physical assets through their life-cycle. This training course will highlight:

Course Benefits:

By attending this WorkmanSkills training course, delegates will be able to:

Target Audience:

It is highly recommended that maintenance, reliability, engineering and technical support staff including leadership and management attend this MAN training course, including:

How will this Training Course be Presented?

This WorkmanSkills training course will utilize a variety of proven learning techniques to ensure maximum understanding, comprehension, and retention of the information presented.

Course Outlines

Module One: Equipment Life-cycle Cost Introduction

Certificate of Completion will be provided to delegates who attend and complete the course

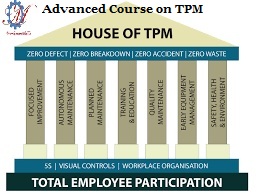

Lower revenues due to lower commodity prices have placed equipment life-cycle costs under the management spotlight like never before. Maintainers are faced with the challenge to deliver the same levels of equipment safety, reliability and availability with smaller budgets. This WorkmanSkills Maintenance & Reliability training course introduces the practical tools and practices that organisations need to adopt to drive down their equipment life-cycle costs in practical ways.

This WorkmanSkills training course emphasizes the most effective strategies, policies, tactics and practices that are needed to ensure the reliability, integrity and durability of the physical assets through their life-cycle. This training course will highlight:

- Financial concepts of costs, capital, profit and return on investment

- The model for asset healthcare

- Cost impact of equipment failure and degradation

- Proactive practices and tools to reduce maintenance costs

- Failure analysis to focus cost reduction efforts

- Work management to improve resource efficiency

Course Benefits:

By attending this WorkmanSkills training course, delegates will be able to:

- Appreciate the structure, content and underlying principles of the CMRP Body of Knowledge

- Understand the Model of Excellence for Maintenance and how to use this to improve company profitability

- Develop effective methodologies to improve Manufacturing Process Reliability

- Describe the key aspects of improving reliability at equipment level

- Utilize leadership skills to achieve maintenance and reliability excellence

- Demonstrate best practice in Work Management, including the principles of managing work flow, planning and scheduling, and shutdown management

- Understand the concepts of costs, capital, profit and ROI

- Understand the cost impact of unanticipated failure

- Apply proactive policies to reduce future maintenance costs

- Structure and analyze failure data to reduce repetitive failures

- Identify root causes of unanticipated failure costs

- Reduce resource costs through efficient work management practices

Target Audience:

It is highly recommended that maintenance, reliability, engineering and technical support staff including leadership and management attend this MAN training course, including:

- Planners

- Supervisors

- Engineers

- Reliability engineers

- Maintenance team leaders and managers

- Operations team leaders and managers

How will this Training Course be Presented?

This WorkmanSkills training course will utilize a variety of proven learning techniques to ensure maximum understanding, comprehension, and retention of the information presented.

Course Outlines

Module One: Equipment Life-cycle Cost Introduction

- Definitions of reliability, maintenance & asset management

- The concept of costs, capital, profits and return on investment

- The ‘Asset Healthcare Model’

- Key areas of asset management

- Open discussion sessions

- The real cost of unanticipated failure

- Asset performance standards

- The forms of asset failure and degradation

- The causes and nature of asset failure and degradation

- The effects, cost and risks of asset degradation

- Programmed maintenance

- Programmed maintenance intervals

- Condition-based maintenance intervals

- Implementing optimized PM programs

- Optimizing spares to support the maintenance program

- Failure data collection and analysis

- The impact of chronic failures versus intermittent failures

- Focus improvement through Pareto analysis

- Quantify losses in life cycle terms

- Rigorous root cause analysis techniques

- Discussion of software and templates to support analysis

- Work identification and defect reporting

- The importance of backlog

- Planning for quality and reliability

- Capacity planning

- Scheduling for efficiency

- Work logistics and preparation

- Checklists and practical aspects work quality control

- Final discussion and evaluation

Certificate of Completion will be provided to delegates who attend and complete the course