An Intensive 3-Day Training Course

Advanced Course on Implementing Effective Preventive and Predictive Maintenance Programmes

Advanced Course on Implementing Effective Preventive and Predictive Maintenance Programmes

Tutor-Led Class @ NGN150,000.00 per Participant

Online @ NGN130,000.00 Per participant

On-Site to make formal request

Venue: Mechelectric Conference Centres, Ikeja, Abuja, PH and Ota

Date and Time: May 5 - 7, 2025; 0900Hr - 1600Hr Daily

Course Overview

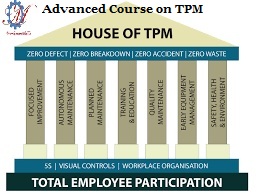

Effective preventive and predictive maintenance are critical for a successful company and an integral part of maintenance management strategies such as RCM, RBM, TPM and 6-sigma. This comprehensive workshop has been designed to benefit both qualified new professional as well as experienced professional who may be involved in the roll-out of a comprehensive maintenance system or auditing an existing system.

This course will discuss how to handle maintenance, process checks, prevent errors, conduct annual audits, and use technology in the department.

Course Benefits

By attending this WorkmanSkills training, delegates will be able to:

Target Audience:

This WorkmanSkills training is ideal for wide range of engineering/maintenance professionals but will greatly benefit:

Works, Services and Maintenance Personnel

How will this Training Course be Presented?

This WorkmanSkills training course will utilize a variety of proven learning techniques to ensure maximum understanding, comprehension, and retention of the information presented.

Course Outlines

*Optimization of Maintenance Decision

· Failure pattern identification

· Statistical analysis of failures

· Wellbull analysis

*Developing the CMNS

· Database construction

. Resources

·Maintenance strategies

*Scheduling

· Long term scheduling with production

· Medium and short term scheduling

· Planning department interface

· Job planning

· Roles and responsibilities

*Key performance indices (KPI)

· Reliability and statistics – MTBF and reliability

· Work request backly analysis

· Customer feedback analysis

*Zero base budgeting

· Define the production requirement

· Define the maintenance

*Failure mode effect and critical analysis (FMECA)

· Causes of failures

· Likelihood and severity of failures – risk analysis

· Reliability centered maintenance

*Reporting

· Monthly PM and PDM reports for management

· Financial feedback reports

· Budget control.

The Certificate

WorkmanSkills Certificate of Completion will be provided to delegates who attend and complete the course

Effective preventive and predictive maintenance are critical for a successful company and an integral part of maintenance management strategies such as RCM, RBM, TPM and 6-sigma. This comprehensive workshop has been designed to benefit both qualified new professional as well as experienced professional who may be involved in the roll-out of a comprehensive maintenance system or auditing an existing system.

This course will discuss how to handle maintenance, process checks, prevent errors, conduct annual audits, and use technology in the department.

Course Benefits

By attending this WorkmanSkills training, delegates will be able to:

- Identify the function of preventive maintenance and its role in organizations

- Use predictive maintenance principles related to asset management

- Describe how to take a successful lead in the management of maintenance operations

- Assess maintenance operations and processes and recommend improvements using the latest best practices

- Evaluate main issues affecting maintenance staff in order to increase their efficiency and productivity

- Apply tools and techniques in Microsoft Excel to effectively manage and monitor maintenance performance

Target Audience:

This WorkmanSkills training is ideal for wide range of engineering/maintenance professionals but will greatly benefit:

Works, Services and Maintenance Personnel

How will this Training Course be Presented?

This WorkmanSkills training course will utilize a variety of proven learning techniques to ensure maximum understanding, comprehension, and retention of the information presented.

Course Outlines

*Optimization of Maintenance Decision

· Failure pattern identification

· Statistical analysis of failures

· Wellbull analysis

*Developing the CMNS

· Database construction

. Resources

·Maintenance strategies

*Scheduling

· Long term scheduling with production

· Medium and short term scheduling

· Planning department interface

· Job planning

· Roles and responsibilities

*Key performance indices (KPI)

· Reliability and statistics – MTBF and reliability

· Work request backly analysis

· Customer feedback analysis

*Zero base budgeting

· Define the production requirement

· Define the maintenance

*Failure mode effect and critical analysis (FMECA)

· Causes of failures

· Likelihood and severity of failures – risk analysis

· Reliability centered maintenance

*Reporting

· Monthly PM and PDM reports for management

· Financial feedback reports

· Budget control.

The Certificate

WorkmanSkills Certificate of Completion will be provided to delegates who attend and complete the course