An Intensive 2-Day Training Course

Optimizing Equipment Maintenance & Replacement Decisions

Optimizing Equipment Maintenance & Replacement Decisions

Tutor-Led Class @ NGN120,000.00 per Participant

Online @ NGN100,000.00 Per participant

On-Site to make formal request

Venue: Mechelectric Conference Centres, Ikeja, Abuja, PH and Ota

Date and Time: November 4 - 5, 2025; 0900Hr - 1600Hr Daily

Course Overview

Major world companies from the process and petrochemical industry have developed their maintenance practices based on the optimization of predictive maintenance management system. This approach works well for both stationary and rotating equipment and includes continuous condition monitoring and the detailed inspection of vital elements of the equipment. The optimization of the maintenance activities includes the spare parts handling, the selection of the right size and skill of maintenance crew with consideration of potential outsourcing i.e. subcontracting. Based on the collected data on reliability of the equipment in operation, Maintenance department can complete the Fitness for Service analysis based on which the decision can be made about 3Rs: Run, Repair or Replace, for the particular component of the equipment. Final decision regarding equipment replacement depends very much on the economic and safety aspect that must be taken into consideration.

This WorkmanSkills training course is intended to introduce the participant to the process of making decisions regarding equipment maintenance optimization including equipment replacement. Various optimization techniques will be presented and the optimization criteria explained. This WorkmanSkills course will also include several workshops with case studies and real world problems to be solved. This will enable all participants to actively take part in the team work and classroom discussions.

The training course will feature:

Course Benefits:

By attending this WorkmanSkills training, delegates will be able to:

Target Audience:

How will this Training Course be Presented?

This WorkmanSkills training course will be conducted along workshop principles with formal lectures and interactive examples, which will result in the active participation of all delegates in discussions and teamwork of problem solving. There will be several class-workshops during which case studies and real life problems will be solved in team work. This will provide understanding of the problems and illustrate the efficient application of modern maintenance optimization technologies. There will be ample opportunities for active, open discussions and sharing professional experiences on various industrial applications. All course materials will be provided.

Course Outlines

Module One: Physical Asset Management & Failure Analysis

The Certificate

Certificate of Completion will be provided to delegates who attend and complete the course

Major world companies from the process and petrochemical industry have developed their maintenance practices based on the optimization of predictive maintenance management system. This approach works well for both stationary and rotating equipment and includes continuous condition monitoring and the detailed inspection of vital elements of the equipment. The optimization of the maintenance activities includes the spare parts handling, the selection of the right size and skill of maintenance crew with consideration of potential outsourcing i.e. subcontracting. Based on the collected data on reliability of the equipment in operation, Maintenance department can complete the Fitness for Service analysis based on which the decision can be made about 3Rs: Run, Repair or Replace, for the particular component of the equipment. Final decision regarding equipment replacement depends very much on the economic and safety aspect that must be taken into consideration.

This WorkmanSkills training course is intended to introduce the participant to the process of making decisions regarding equipment maintenance optimization including equipment replacement. Various optimization techniques will be presented and the optimization criteria explained. This WorkmanSkills course will also include several workshops with case studies and real world problems to be solved. This will enable all participants to actively take part in the team work and classroom discussions.

The training course will feature:

- Main types of equipment failure mechanisms

- Maintenance methodologies and economic aspects

- Spare parts handling and storage modeling

- Risk assessment and management

- Equipment inspection and fitness for service analysis

Course Benefits:

By attending this WorkmanSkills training, delegates will be able to:

- Identify equipment failures, and the impact on plant reliability

- Understand the cost-effectiveness of Preventive/Predictive Maintenance program

- Apply techniques of optimization of various maintenance activities

- Define criteria for work-crew size, spare parts and equipment replacement

- Make the important decision on the basis of the cost and benefit analysis

- Incorporate safety objectives to the equipment repair or replacement optimization

Target Audience:

- Operation, technical production & service professionals

- Technical professionals responsible for maintenance and repair of equipment

- Professionals involved in inspection and reliability

- Technical professionals dealing with risk assessment and integrity analysis

- Technicians dealing with regulating and metering and other measurements

How will this Training Course be Presented?

This WorkmanSkills training course will be conducted along workshop principles with formal lectures and interactive examples, which will result in the active participation of all delegates in discussions and teamwork of problem solving. There will be several class-workshops during which case studies and real life problems will be solved in team work. This will provide understanding of the problems and illustrate the efficient application of modern maintenance optimization technologies. There will be ample opportunities for active, open discussions and sharing professional experiences on various industrial applications. All course materials will be provided.

Course Outlines

Module One: Physical Asset Management & Failure Analysis

- Physical Asset Management

- Maintenance Management: Preventive / Predictive Approach

- Nature and Modes of Equipment Failure

- Failure Modes & Effect Analysis (FMEA)

- Analysis of Component Failure data using the Weibull Distribution

- Censored Data, the 3-Parameter Weibull, and the Kolmogorov-Smirnov Test

- Reliability and Availability Concept: MTBF & MTTR

- Reliability Improvement through Reduction of Downtime

- Maintenance Performance Quantification

- Preventive Maintenance & Spare Part Handling

- Spare Parts Provisioning: Prediction Models and Techniques

- Management of Change: In-Kind Spare Parts

- Condition Monitoring & Inspection

- Risk Based Inspection (RBI)

- Risk Matrix: Management and Mitigation Measures

- Reliability Improvement through Inspection

- Inspection Scope & Frequency

- Fitness for Service Analysis (FFS)

- Management of Maintenance Resources

- Effective Use of CMMS

- Maintenance Organization Analysis : Crew size

- Equipment Repair or Replacement Decision

- Economic Aspect of Maintenance Outsourcing: Subcontract

- Economic Aspect of Equipment Replacement

- Capital Investment in Equipment and Maintenance: ROI

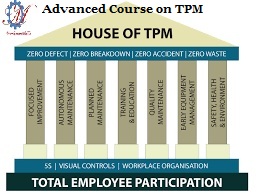

- Total Productive Maintenance

- Safety in Maintenance Work

- KPI and OEE: Leading and Lagging Indicators

- Summary and Conclusions

The Certificate

Certificate of Completion will be provided to delegates who attend and complete the course